In maritime and industrial sectors, reliability is paramount. Auxiliary engines play a crucial role in supporting various operations, powering generators, pumps, compressors, and HVAC systems onboard ships, and driving diverse industrial machinery. Ensuring their uninterrupted operation hinges upon regular servicing and having access to reliable spare parts. This article explores the significance of auxiliary engine spare parts and the benefits of proper management.

Importance of Auxiliary Engine Spare Parts

- Enhancing Reliability: Regular servicing and timely replacement of worn-out parts significantly enhance the reliability of auxiliary engines. High-quality spare parts ensure engines perform as expected, reducing the risk of breakdowns.

- Cost Optimization: While acquiring spare parts involves initial costs, it ultimately leads to long-term savings. Regular maintenance and timely replacement prevent major damages that could necessitate costly repairs or even engine replacement.

- Compliance: Many industries are subject to stringent regulations regarding equipment maintenance and safety. Having the right spare parts and conducting regular replacements is essential for compliance and avoiding penalties.

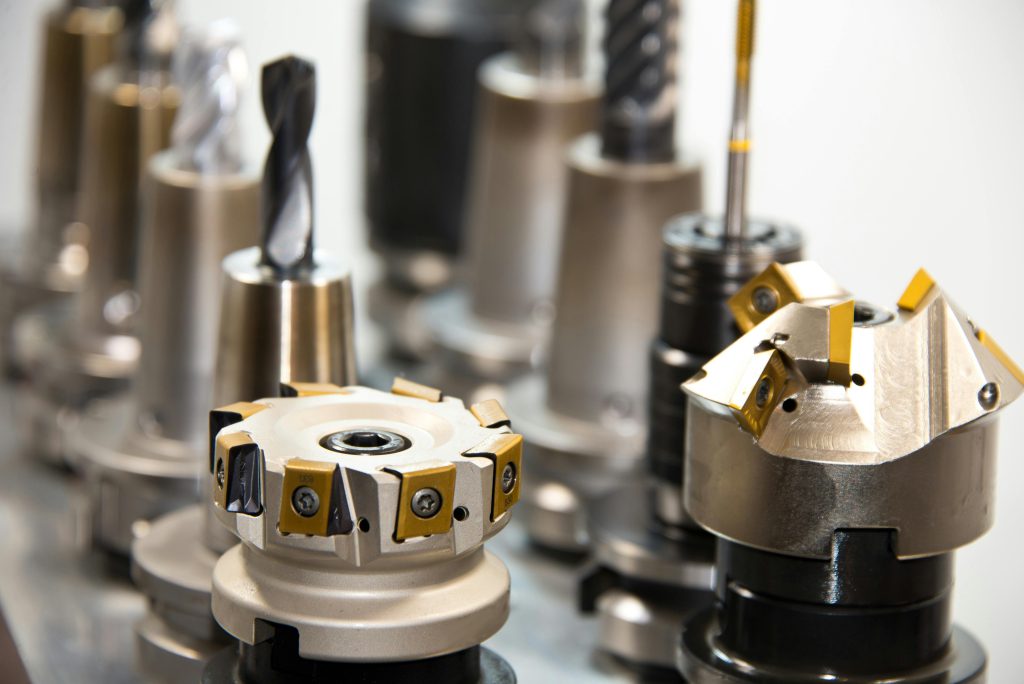

Types of Auxiliary Engine Spare Parts

Among the most commonly replaced auxiliary engine spare parts are:

- Filters: Air, oil, and fuel filters are critical for maintaining engine cleanliness and proper operation. Regular replacement prevents contamination that could lead to engine damage.

- Gaskets and O-rings: These components ensure system sealing and prevent leaks. Over time, they wear out and require regular inspection and replacement.

- Drive Belts: Responsible for transferring power from the engine to other components, drive belts wear out over time and may break, halting engine operation.

- Bearings: Bearings facilitate smooth operation of moving engine parts. Worn or damaged bearings can increase friction and mechanical failures.

- Spark Plugs and Injectors: Essential for efficient fuel combustion and engine performance. Regular replacement of these components ensures optimal engine efficiency.

Spare Parts Management

Efficient spare parts management is crucial for operational continuity. Here are some key strategies:

- Maintenance Planning: Regular inspections and maintenance help detect worn-out parts early, allowing for timely replacement before failures occur.

- Inventory Management: Well-organized spare parts inventory with accurate stock records prevents shortages of critical components.

- Supplier Relationships: Maintaining good relationships with spare parts suppliers ensures quick access to needed items and technical support.

Implementing Maintenance Strategies

- Predictive Maintenance: Utilizing predictive maintenance techniques, such as vibration analysis and thermal imaging, helps anticipate potential issues before they escalate. This proactive approach minimizes unplanned downtime and optimizes the lifespan of auxiliary engines.

- Condition Monitoring: Implementing continuous condition monitoring systems allows for real-time assessment of engine health. Monitoring parameters such as temperature, pressure, and vibration levels enables early detection of abnormalities, prompting timely maintenance actions.

- Performance Analytics: Leveraging data analytics to analyze engine performance metrics provides valuable insights into operational efficiency and identifies trends or patterns that may indicate the need for specific spare parts replacements or adjustments.

How to get the best parts

Ensuring reliability and efficiency of auxiliary engines in maritime and industrial sectors is crucial. Effective spare parts management plays a pivotal role here. Explore our comprehensive guide on auxiliary engine spare parts and discover the benefits of proper management and regular servicing. Stay operational – read now! https://posejdon-marine.pl